Pouring and placing concrete for flatwork or vertical elements of a building has always been one of my favorite construction processes to watch be installed.

All the hours spent digging, scraping and proof rolling the ground, then establishing building corners installing below grade utilities, installing reinforcing steel, forming areas to contain the concrete pour. Then pour day happens, these activities most often occur in the wee hours of the morning or sometimes during the midnight shift. All to create optimal mix times, chemistry, and atmospheric conditions.

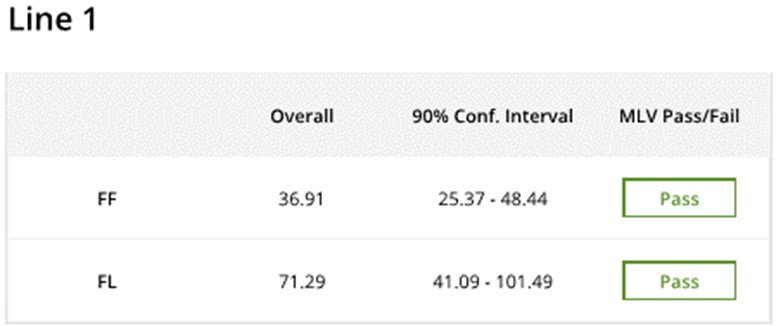

The concrete is poured out from trucks and buggied or pumped into place, then trade workers scurry to place, level, flatten and shine that concrete floor. Then after the concrete is setup a test is done, to determine how flat and level (fF/fL) the floor was installed, typically days later.

If it is not installed in accordance with the spec the floor must be replaced, be ground, or have a topping placed on it. No doubt the floor will be compromised for future use over the life of the building. Over the course of my life I have heard many remarks about inferior flatwork, yet I never witnessed someone identify a true mechanism to fix it in a proactive manner.

|

|

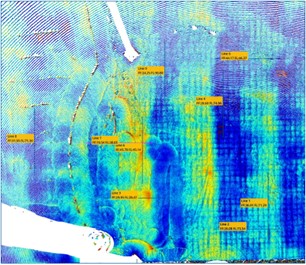

That is until now. In 2020 Trimble came out with the X7 Laser Scanner. It has been incredibly disruptive in the market because of its capabilities and versatility. However, the software version 5.8 of FieldLink now adds in the ability to view floor data live while crews are working. Cycle a scan of the pour in less than 4 minutes, process it on the device, and have a map with layout markers of high and low areas of the floor within 5 minutes.

Then get out and “cut the bumps” then trowel the floor and scan it again, this time running a fF / fL analysis with a report to document the condition of the finished floor. This device will “flat out” change how concrete floors and shafts are placed and documented for years to come.

Corey Bell

General Manager

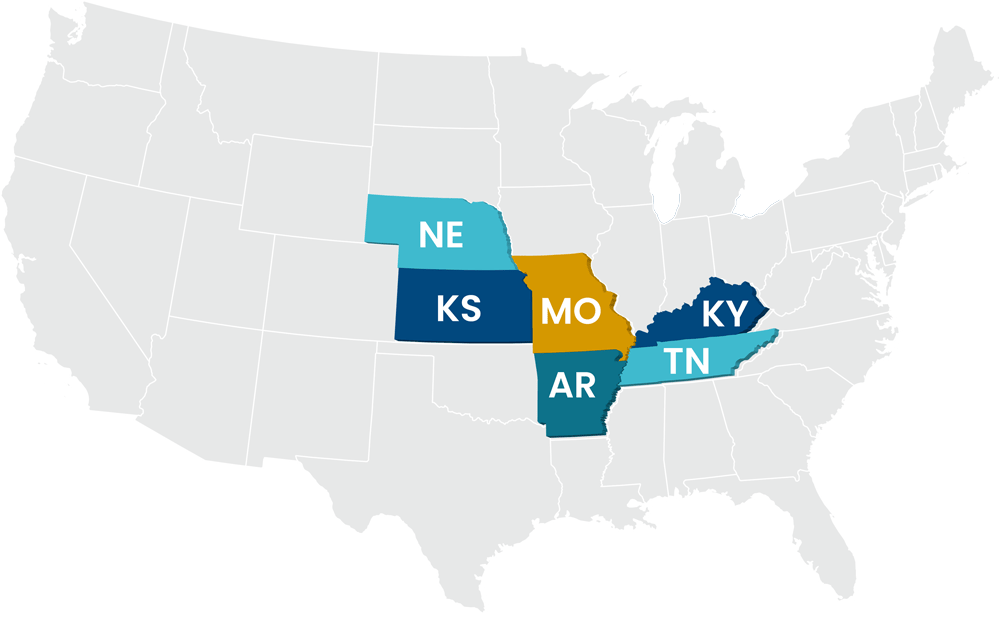

BuildingPoint Mid-America